Views: 0 Author: Site Editor Publish Time: 2025-07-07 Origin: Site

You do a quality inspection by following easy steps. First, you decide what your quality standards are. Then, you check the products with a trusted inspection process. You look for problems, count the order, and test important parts. Doing things in order helps you get good results each time. Marsky is a top inspection company in China. They help you watch product quality at every step. Many companies trust Marsky for supplier audit and quality inspection jobs.

Follow simple steps for quality inspection. Set standards first. Check products closely. Test important parts. This helps get the same results each time.Use different inspection types. Do pre-production checks. Inspect during production. Check before shipping. Watch container loading. These steps help find problems early. They also protect your brand.Get ready by setting clear rules. Train your team well. Gather the right tools. Plan inspections to reach quality goals. Make sure you follow industry rules.Check products by taking samples. Look at them carefully. Measure them. Test how they work and if they are safe. Find and fix problems quickly.Keep good records. Share clear reports. This helps improve quality over time. It also keeps your supply chain strong and trustworthy.

You want your business to grow and succeed. A strong focus on quality helps you reach that goal. When you use a reliable inspection service, you protect your brand and keep your customers happy. Quality inspections help you spot problems early. You can fix issues before they reach your buyers. This saves you money and time. You also avoid costly returns and complaints.

Note: Many companies choose Marsky for their quality assurance needs. Marsky checks products in many categories, such as electronics, apparel, and household goods.

You also build trust with your customers. When you deliver products that meet high standards, people come back to buy again. You can use supplier audit services to check if your partners follow the right steps. This gives you more control over your supply chain. The importance of an inspection grows as your business expands. You need to make sure every order meets your requirements.

Defects can hurt your business. They can lead to unhappy customers and lost sales. You need to find defects before your products leave the factory. Quality inspections help you do this. You can check for defects in size, color, function, and packaging. Marsky uses detailed checklists to look for defects at every stage.

You can use tests like barcode scans and carton drop tests to find hidden defects.

You can also check the appearance and function of each item.

Quality assurance means you look for defects and fix them fast. This keeps your products safe and reliable. You can use inspection service tools to track and report defects. This helps you improve your process over time.

You need to know the main types of quality control inspection. This helps keep your products safe and reliable. Each step lets you find problems early. It also helps protect your brand. Marsky gives you different types of quality control inspections for your needs.

You begin with a pre-production inspection, called PPI. This step checks raw materials and parts before making products. You make sure the materials meet your quality standards. If you find problems now, you can fix them early. This saves time and money. This is an important part of incoming quality control. Electronics, clothes, and home goods all need this early check.

Next, you use in-process quality control. Marsky calls this Initial Production Inspection (IPI) and During Production Inspection (DPI). You check products when 10% to 80% of the order is done. You look for defects and make sure the line follows your rules. Random inspection at this stage helps you find problems early. You can change the process and stop delays. This step is important for electronics and soft goods.

You need a last random inspection before shipping. Marsky’s Pre-Shipment Inspection (PSI) checks if finished goods match your order. The team uses random inspection to pick samples. They check how many items, packaging, and product quality. They also test function, safety, and looks. The main goal is to make sure you get what you ordered. The final inspection report shows if the shipment passes or fails. This step in the quality control process protects your name and stops bad goods from reaching your customers.

Tip: Always ask for a detailed final random inspection report. It helps you decide if you should accept or reject the shipment.

The last step is container loading supervision (CLS). You want to make sure the right products and amounts go into the container. The team checks carton conditions, packaging, and labels. They watch the loading and seal the container. They write down everything and give you a report with photos. This random inspection lowers the risk of damage or missing items during shipping. You feel better knowing your goods are safe.

Types of quality inspections like these help you control every part of your supply chain. You use random inspection and final random inspection to keep your quality high. Marsky’s quality control inspection services cover electronics, clothes, and many other products. You can trust their quality control processes to give good results.

You must get ready before you start an inspection. Good preparation helps you follow each step. It also helps you reach your quality goals. Marsky uses a checklist that works well. You can use these steps to make sure your plan covers everything important.

First, set clear inspection criteria. Every inspector should check the same things. This way, you get the same results each time. Use a master checklist template for your product. It should list size, weight, color, and function. If you check home appliances or clothes, add voltage, fabric type, or stitching. Attach instructions and example pictures to your checklist. This helps everyone know what to look for. It keeps your plan on track. Ask inspectors to take photos if something is not clear. This gives feedback and helps you get better. Train your team to use the same methods. They should always check the specifications and compliance standards.

Tip: Make sure your inspection plan matches your quality goals and industry rules. This helps you follow the rules and make fewer mistakes.

Pick the right people for your inspection team. Each person should know the product and the plan. Your team needs to understand the rules and standards. Marsky says you should train your team. This way, everyone does the steps the same way. Good training makes your results better.

Get all the tools you need before you start. Use measuring devices, barcode scanners, and safety test tools. Make sure you have the newest checklists and guides. For electronics or clothes, you may need special tools. The right tools help you check specifications and compliance. Having tools ready is very important.

Make a detailed inspection plan that fits your needs. Think about the supplier’s history, product value, and safety risks. Some products need more checks if they have many parts or strict rules. Use your plan to set the schedule and give out tasks. Track your progress as you go. Make sure your plan covers all points. Update your plan often if rules or designs change.

Note: Marsky’s plan checks quantity, packaging, looks, and function. This helps you meet all rules and quality needs.

A good quality control inspection has clear steps. You need to check each part to make sure your products are right. Marsky uses a trusted inspection process. They check things like quantity, looks, and how things work. Let’s see what happens in each step of the quality inspection.

You begin with sampling. You cannot look at every item in a big order. So, you pick a few items that show what the whole batch is like. This step helps make the inspection fair and correct.

Simple random sampling means every item can be picked. This way, you do not favor any item.

Stratified sampling is good when your products have different groups. You split the batch into groups and pick from each group. This lets you check all types, like different sizes or colors.

Non-probability methods like quota or purposive sampling are for special cases. But these can make the results unfair.

Always watch out for mistakes in sampling and pick the right number of items. This helps you trust your results.

Marsky uses the acceptance quality level (AQL) standard to decide how many items to check. This makes sure the random inspection checks enough products to find problems.

Next, you do visual checks. You look at how the product and packaging look. You compare each item to your rules. You check color, shape, and surface finish. For example, you might look for scratches or stains on household items. You also check labels, logos, and shipping marks.

Marsky’s inspectors use a checklist so they do not miss anything. They look for problems like color changes, wrong prints, or broken boxes. You can use a color test to see if the product matches your sample. If you find a problem, you take pictures and write it down for your report.

Tip: Always look at the box and packaging in this step. Good packaging keeps your products safe when shipping.

You need to measure and test your products to make sure they are right. Use tools like rulers, calipers, and scales. For machines, you check size, weight, and shape. For clothes, you measure fabric and stitching.

Marsky’s team does tests like:

Barcode scan test: You scan the barcode to see if it matches your records.

Carton drop test: You drop the box from a set height to check if the packaging protects the product.

Color test: You compare the product color to your standard.

These tests help you see if the product passes your quality check. You write down all results in your inspection report.

You must check if your product works right. This is important for electronics, toys, and home appliances. You test buttons, switches, and moving parts. For example, you turn on a light or run a blender to see if it works.

Safety tests keep your customers safe. You look for sharp edges, loose parts, or electric dangers. Marsky’s inspectors follow strict safety rules. They use special tools to check for risks. If you find a problem, you mark it as a defect and report it right away.

Note: Always follow the last quality control steps for products with strict safety rules. This keeps your customers safe and your brand strong.

You need to find and write down all defects during your quality control inspection. Defects can be minor, major, or critical. Each type helps you decide if you should accept or reject the shipment.

Here is a table showing common defect types in different industries:

Industry | Minor Defect Examples | Major Defect Examples | Critical Defect Examples |

|---|---|---|---|

Garment | Small loose threads, slight color change, small stitching mistakes | Crooked seams, broken zippers, fabric damage that changes how it looks or works | Wrong size, dangerous materials, bad build making the garment unsafe |

Electronics | Scratches you cannot see, small looks problems | Broken buttons, bad ports, screen problems that make it hard to use | Electric shorts, battery leaks, problems that can hurt people |

Automotive | Small paint scratches, trim not lined up, looks problems that do not change how it works | Bad door latches, air conditioning does not work, electric errors that make it hard to use | Brake does not work, airbag does not work, problems that can hurt the driver or passengers |

You must check for all kinds of defects. Marsky’s inspectors use a checklist to help with this step. They write down every defect and add photos in the final inspection report. This helps you decide if you should accept the shipment.

A full quality control inspection checks every detail. You follow these steps to keep your brand safe and give your customers good, safe products.

Clear documentation and reporting help you keep control over your quality inspection process. You need to record every detail, create useful reports, and share results with your team. This step makes sure you meet compliance rules and keep your products safe.

You start by writing down everything you see during the inspection. Use a checklist to track each item. For example, you can note the size, color, and function of electronics or household products. Take photos of any problems. Write down the results of each test, such as barcode scans or carton drop tests. If you find any issues, you must report defects right away. Good records help you prove that you followed the right steps and met compliance standards.

Tip: Use digital tools or an inspection report template to make your notes clear and easy to read.

After you finish the inspection, you need to make a report. This report should include all your findings, photos, and test results. Marsky uses a final inspection report to show if the products meet your quality standards. The report lists every check, from packaging to function. It also shows if the products pass or fail compliance checks. You can use this report to decide if you should accept the shipment. A good report helps you track trends and improve your quality control over time.

Include these parts in your report:

Product details

Inspection date and location

List of tests and results

Photos of defects

Comments on compliance

You must share the inspection results with your team and suppliers. Send the final inspection report to everyone involved. This helps you fix problems fast and keep your supply chain strong. If you work with Marsky, you get clear reports that make it easy to see what needs attention. Good communication helps you meet compliance goals and keep your quality high. Always follow up on any issues to make sure they get fixed before shipping.

Note: Sharing results quickly helps you avoid delays and keeps your customers happy.

Good planning, talking clearly, and always trying to get better are important for a quality control inspection. You can follow these best ways to make sure your inspections work well for your business.

Checklists help you stay organized during every inspection. When you use a checklist, you make sure each step is done the same way. This helps stop mistakes and keeps your checks the same, even if different people do them. You can use checklists for electronics, clothes, or other products. Digital checklists, like the ones from Marsky, let you see updates right away and share them with your team.

Make your inspection steps the same so you do not miss anything.

Lower mistakes by following a simple list.

Save a record of each inspection for later checks.

Teach new inspectors fast by using the same checklist.

Use digital tools to help your team work together and report results.

Tip: A checklist is very helpful for a good quality control inspection.

Some problems can stop you from having a good inspection. You should watch out for these mistakes:

Not getting ready or skipping training.

Using the wrong tools or missing needed equipment.

Not writing down what you find.

Only using technology and not thinking for yourself.

Not making clear rules for the inspection.

You can stop these mistakes by making sure your team is trained and has the right tools. Always keep good notes and use both tech and your own skills. Talking clearly with your team and suppliers helps stop confusion. Marsky’s inspection services give you strong steps and skilled inspectors.

A good quality control inspection does not stop after one check. You need to keep making your process better. Use the Plan-Do-Check-Act cycle to plan changes, try them, and see what works. Get feedback from each inspection and use it to make the next one better. Marsky’s tools help you watch results and see patterns over time.

Check raw materials when they come in.

Look at products while they are being made.

Test finished goods before they are shipped.

You can use ways like Six Sigma or Total Quality Management to lower defects and get better results. When you keep improving, you build a strong system for quality control. This keeps your products safe and your customers happy.

Note: Feedback and teamwork help you reach higher goals with every quality control inspection.

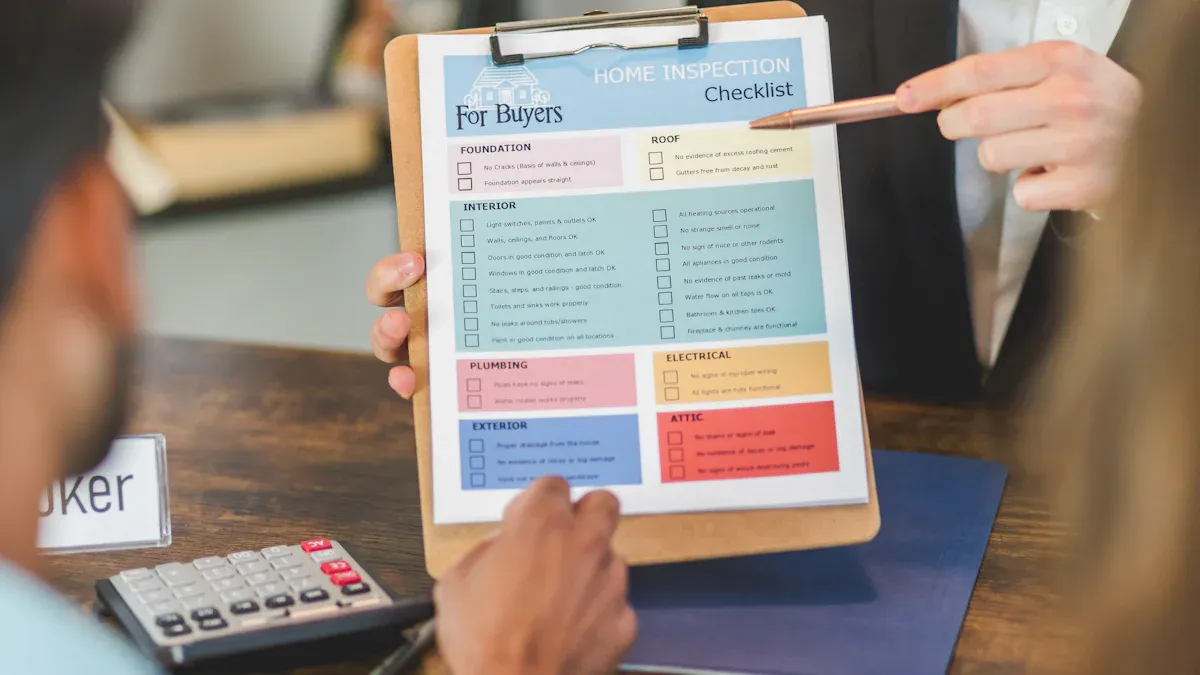

You need a simple checklist to help with your inspection. This makes sure you check every important part. It also helps you not forget any steps. Start by looking at the outside of the product. Then, check the inside parts. Here is an easy list you can use for electronics, clothes, or other things:

Look at the outer packaging for damage, labels, and shipping marks.

Count all items and see if it matches the order.

Check the size, weight, and materials of the product.

Make sure colors, logos, and branding are correct.

Scan barcodes and check labels for the right rules.

Look for safety and regulatory marks, like CE or FCC.

Check for visual defects, such as scratches or stains.

Test if the product works as it should.

Do any needed safety or destructive tests.

Write down sample sizes and use the right tools.

Mark each item as pass or fail using clear rules.

Take photos of any problems or defects you find.

Update your checklist after each inspection to keep it right.

Tip: Always use this checklist for every inspection. It helps your process stay strong and dependable.

You can use this table to help you during your inspection. It lets you track each step and see results quickly.

Step | What to Check | Pass/Fail | Notes/Photos |

|---|---|---|---|

Outer Packaging | Damage, labels, shipping marks | ||

Quantity | Item count vs. order | ||

Dimensions & Weight | Size, weight, materials | ||

Colors & Branding | Colors, logos, labeling | ||

Barcode & Compliance | Barcode scan, CE/FCC marks | ||

Visual Inspection | Scratches, stains, defects | ||

Function & Performance | Product works as intended | ||

Safety Tests | Electrical, drop, or other tests | ||

Sample Size & Tools | Enough samples, right equipment | ||

Defect Photos | Take and attach photos |

This checklist can be used for many products, like electronics and clothes. You can change it to fit what you need. Marsky’s inspection service uses a checklist like this to help keep your products safe and your customers happy.

You get better results if you follow clear steps for quality inspections. Checklists and good records help you find problems in electronics or clothes early. Always try to make your process better. Marsky gives expert inspection services to help you reach high standards. Keep learning new ways and change your inspection steps to stay successful.

You count the products and check how they look. You also check their size and if they work right. You test the packaging, labels, and safety too. Marsky’s team follows a checklist for every step. This helps you find problems in electronics, toys, or furniture before they ship.

A third party inspection company like Marsky gives fair results. Their inspectors know the local factories well. This helps you avoid problems and makes sure your products meet your needs.

You should check products before making them, while making them, and before shipping. Regular checks help you find problems early. This keeps your supply chain strong and your customers happy.

Marsky writes down all problems and takes photos. You choose if you want to fix, replace, or reject the goods. This keeps your brand safe and helps you avoid costly returns.

Yes! Marsky checks electronics, clothes, toys, furniture, and more. You can trust their team to follow strict quality control steps for every type of product.