Views: 0 Author: Site Editor Publish Time: 2025-08-14 Origin: Site

Electronic Manufacturing Services drive innovation and scalability across the electronics industry. Companies rely on EMS to design, assemble, and test products efficiently. Over 60% of original equipment manufacturers outsource production, while nearly 70% of consumer electronics companies depend on EMS providers for assembly. The EMS market reached USD 626.8 billion in 2024 and continues to grow, fueled by demand for electric vehicles and IoT adoption.

| Metric | Value |

|---|---|

| Market size in 2021 | USD 500 billion |

| Market size in 2024 | USD 626.8 billion |

| Projected market size by 2030 | USD 750 billion |

| CAGR (2022-2030) | Approximately 6% |

Choosing the right EMS partner ensures product quality and operational efficiency.

Electronic Manufacturing Services (EMS) help companies design, build, test, and deliver electronic products efficiently and at scale.

EMS providers offer a wide range of services including design support, manufacturing, quality testing, supply chain management, and post-production care.

Choosing the right EMS partner improves product quality, reduces costs, and speeds up time-to-market.

EMS companies use advanced technology like automation, AI, and IoT to ensure high quality and flexible production.

Strong EMS partnerships protect intellectual property and support innovation across many industries such as automotive, medical, and consumer electronics.

Electronic Manufacturing Services represent a specialized sector within the electronics industry. Companies in this field offer a comprehensive suite of solutions that support the entire product lifecycle. These solutions include design, prototyping, manufacturing, testing, and logistics. EMS providers assist with conceptual product development, mechanical and electrical design, and software integration. They also manage component sourcing, global supply chain operations, and inventory control.

Testing and quality control form a core part of EMS. Providers use advanced methods such as Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and Statistical Process Control (SPC) to ensure products meet strict standards. EMS companies often adopt the E2MS strategy, which integrates product development, prototyping, industrialization, and testing phases. This approach enables faster ramp-up and streamlined mass production.

EMS providers play a vital role in maintaining high reliability and environmental robustness for products in sectors like medical devices and automotive. They implement supplier quality management through audits and performance reviews, ensuring only quality components enter the production process.

The scope of Electronic Manufacturing Services extends across the global electronics ecosystem. EMS companies handle production, testing, distribution, and repair of electronic components and assemblies. Their technological capabilities include automation, robotics, IoT integration, and lean manufacturing. These features allow EMS providers to deliver scalable and cost-effective solutions.

Industry analysts describe EMS as a critical partner for original equipment manufacturers (OEMs). EMS companies enable OEMs to focus on research and development and brand management by taking over manufacturing responsibilities. The sector has a global footprint, with significant activity in Asia Pacific, the United States, China, and Europe. Asia Pacific leads due to its proximity to suppliers and OEMs, favorable regulations, and strong demand in consumer electronics, automotive, healthcare, and aerospace.

| Aspect | Description/Details |

|---|---|

| Scope of EMS Sector | Extensive and integral to the electronics industry ecosystem; includes production, testing, distribution, and repair of electronic components and assemblies. |

| Services Provided | Production, testing, distribution, repair; enabling OEMs to focus on R&D and brand management. |

| Technological Capabilities | Use of automation, robotics, IoT integration, lean manufacturing, economies of scale. |

| Geographic Reach | Global presence with significant activity in Asia Pacific, U.S., China, Europe, and others. Asia Pacific dominates due to proximity to suppliers and OEMs. |

| Market Size & Growth (2024) | Global EMS and ODM market estimated at US$1.1 Trillion in 2024, expected to grow to US$1.8 Trillion by 2030 (CAGR 9.5%). EMS segment CAGR 9.8%, ODM 8.5%. |

| Regional Market Highlights | U.S. market at US$71.1 Billion (2024); China forecast to grow at 10.3% CAGR reaching US$540.6 Billion by 2030; Japan and Canada growing at 7.0% and 8.6% CAGR respectively; Germany at 7.4% CAGR. |

| Market Drivers | Increasing product complexity, rapid tech advancements, globalization of supply chains, cost pressures, IoT integration. |

| Role in Industry | Pivotal partners for OEMs, supporting rapid innovation, short product lifecycles, scalable and cost-effective manufacturing solutions worldwide. |

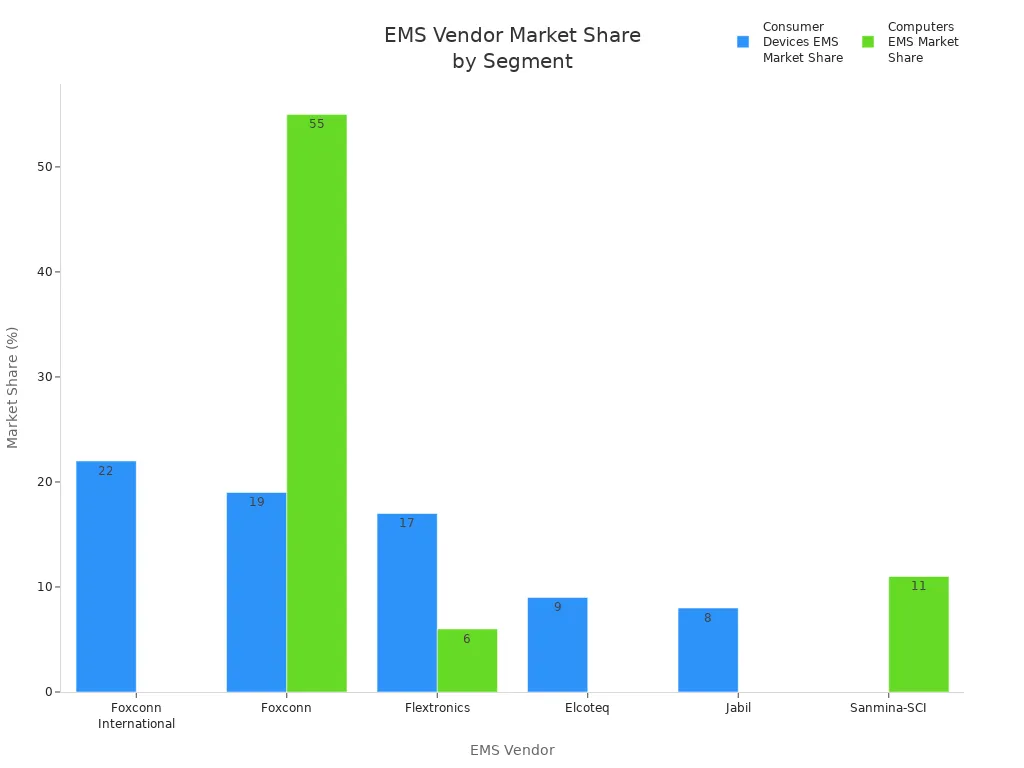

EMS providers serve multiple market segments. Consumer devices, such as mobile phones and TVs, account for the largest share of EMS activity. Computers, servers, storage, networking, telecom, and emerging sectors like automotive and medical electronics also rely heavily on EMS.

| Segment | Description/Scope | Combined EMS & ODM Market Share | EMS Market Share within Segment | Top EMS Vendors and Their Shares (EMS Market) |

|---|---|---|---|---|

| Consumer Devices | Mobile phones, set-top boxes, flat-panel TVs, videogame systems, portable music players, digital cameras, handheld devices | 27% | 75% EMS / 25% ODM | Foxconn International Holdings (FIH) 22%, Foxconn 19%, Flextronics 17%, Elcoteq 9%, Jabil 8% |

| Computers | Desktop and mobile PCs | N/A (ODM dominant) | 19% | Foxconn 55%, Sanmina-SCI 11%, Flextronics 6% |

| Other segments | Servers and storage, Networking, Telecom, Peripherals, Emerging (automotive, medical, industrial electronics) | Not specified | Not specified | Not specified |

Electronic Manufacturing Services continue to expand as product complexity increases and technology advances. EMS companies adapt quickly to market changes, offering flexibility and expertise that support innovation and growth across industries.

Leading EMS providers offer a broad range of design and development services to help clients bring products to market quickly and efficiently. These services include:

Front-end electronics design

Hardware and firmware design

Embedded systems design

Design-for-manufacturing (DfM)

Rapid prototyping

Joint design collaborations (JDM)

EMS companies employ skilled electrical engineers who support new product introductions and ensure that designs are ready for manufacturing. Their design capabilities often overlap with those of original design manufacturers (ODMs), allowing for a seamless transition from concept to production. By leveraging these services, original equipment manufacturers (OEMs) can accelerate time-to-market, improve product quality, and stay competitive.

EMS providers have evolved beyond manufacturing. They now offer end-to-end solutions such as design prototyping, regulatory support, and supplier management. This shift enables faster product innovation, especially in industries like medical devices. Their exposure to new technologies and cross-industry knowledge helps clients adopt innovative materials and processes. Using proven EMS solutions reduces development time and costs, helping companies launch products faster.

European EMS companies, for example, invest in automation and digitalization, which increases productivity and quality. Customer-focused collaboration and streamlined order handling reduce lead times and lower costs. These advancements directly contribute to faster product development cycles and greater innovation speed.

Top EMS companies provide comprehensive manufacturing and assembly services. Their capabilities include:

PCB assembly using surface mount technology (SMT) and through-hole technology (THT)

Cable and electromechanical assembly

Prototype development and testing

Full product assembly, including installation of components, connectors, and cables

Conformal coating and product certification

Repair, revision upgrading, and aftermarket services

These providers use automation and artificial intelligence to improve efficiency and precision. They manage the entire process, from design and prototyping to mass production. Their global networks allow for scalable production while maintaining strict quality standards.

During manufacturing, EMS companies perform PCB fabrication, component placement, soldering, inspection, and testing. They collaborate with clients to optimize product designs for manufacturability, ensuring smooth transitions from prototype to full-scale production.

Testing and quality control are critical in Electronic Manufacturing Services. EMS providers use a variety of procedures to ensure products meet high standards:

Design for Manufacturability (DFM) reviews

Incoming material inspections

Statistical Process Control (SPC)

Rigorous environmental, functional, and electrical testing

Component management to prevent counterfeit parts

Process management with defined procedures

Data analysis to detect defects

Bill of Materials (BOM) health evaluations

Process Failure Mode and Effects Analysis (PFMEA)

New Product Introduction (NPI) processes

Providers use advanced equipment such as automated optical inspection (AOI), X-ray machines, and high-resolution cameras. Robust document control and incident management systems help track and resolve quality issues quickly.

Marsky stands out in this area. The company offers factory inspection, company verification, quality control, and supplier audits. Marsky integrates AI-powered inspection, micron-level detection, and real-time monitoring. Their on-site inspections, robotic systems, and non-destructive testing ensure comprehensive coverage. Marsky delivers timely, detailed reports, often within 24 hours, and maintains a high supplier rating.

| Aspect | Details |

|---|---|

| Company Name | Marsky |

| Experience | 12+ years |

| Supplier Rating | 4.8/5 based on 158 reviews |

| Service Scope | Factory inspection, company verification, quality control, supplier audits, final product inspection |

| Technology Integration | AI-powered inspection, micron-level detection, real-time monitoring, automated reporting |

| Inspection Methods | On-site inspections, robotic inspection, high-resolution cameras, non-destructive testing |

| Reporting | Timely, detailed analysis, comprehensive coverage |

| Differentiation | Combines AI-enhanced inspection and audit services with a strong track record and high supplier rating |

Marsky provides fast reporting, broad coverage across China, and deep expertise in product inspections and audits, making it a trusted partner for EMS quality assurance.

EMS companies manage complex supply chains to ensure timely delivery and cost efficiency. They integrate sourcing, logistics, production, sales, operations, engineering, and marketing to align supply chain goals with business objectives. Prompt decision-making and continuous market monitoring help them adapt to changes in lead times or supply interruptions.

Strong EMS partnerships focus on optimizing the Bill of Materials (BOM), lean manufacturing, scalability, and demand forecasting. Early collaboration with OEMs reduces lead times and costs. Providers build resilient supply chains through multi-sourcing, risk mitigation, and contingency planning. They use technology for visibility and transparency, integrating ERP systems and sharing forecasts to improve responsiveness.

Effective communication and collaboration throughout the project lifecycle are essential. EMS providers maintain robust relationships with suppliers, employ inventory management, and implement risk mitigation strategies. Their logistics capabilities ensure smooth transportation and delivery of finished products.

Common challenges in supply chain management include data integrity issues, insufficient user training, managing large volumes of data, integration with OEM ERP systems, and third-party software compatibility. EMS providers address these challenges by investing in training, data validation, and technology integration.

Post-production support extends the value of Electronic Manufacturing Services. EMS companies offer a range of services to maintain product quality and customer satisfaction:

Repair and rework

Refurbishment

Product upgrades

Warranty service

Manual touch-up

Dedicated project management

Manufacturing consultations

Design for manufacturing (DFM) support

New Product Introduction (NPI) assistance

These services help extend product lifecycles and ensure continued performance. Aftermarket support, including repair and maintenance, allows clients to address issues quickly and efficiently. EMS providers also offer reverse logistics for returns, recycling, or refurbishment, supporting sustainability and cost savings.

Electronic Manufacturing Services (EMS) and Original Equipment Manufacturers (OEM) play distinct roles in the electronics industry. EMS providers focus on manufacturing, testing, distributing, and repairing electronic components and assemblies for OEMs. In contrast, OEMs create original product designs and manage their brands, often outsourcing production to EMS partners.

The following table highlights the key differences between EMS and OEM:

| Aspect | Electronics Manufacturing Services (EMS) | Original Equipment Manufacturers (OEM) |

|---|---|---|

| Primary Role | Manufacture, test, distribute, and repair electronic components and assemblies on behalf of OEMs. | Original creators of product designs and brands. Often outsource manufacturing to EMS. |

| Service Scope | Manufacturing, testing, warranty, repairs, design services, prototyping, tooling, logistics, and sometimes full product development and IP involvement. | Focus on product innovation, brand management, and market strategy. Manufacturing often outsourced. |

| Value Proposition | Manufacturing expertise, cost efficiency, scalability, economies of scale, flexibility, and handling complex supply chains. | Focus on innovation and marketing without heavy capital investment in manufacturing infrastructure. |

| Strategic Focus | Operational excellence in production and supply chain management, expanding into design and development services. | Product design, brand ownership, and market positioning. |

| Evolution | Expanded from PCB fabrication to include system assembly, design, testing, delivery, warranty, repair, and software services. | Maintain core competencies in product innovation and outsource production to leverage EMS capabilities. |

EMS providers enable OEMs to focus on innovation and brand strategy while handling the complexities of manufacturing and supply chain management.

EMS and contract manufacturing both involve outsourcing production, but EMS providers deliver a broader range of services and greater flexibility. Contract manufacturing typically centers on producing goods based on OEM specifications, often limited to a single facility. EMS companies, however, offer end-to-end solutions, including design support, supply chain management, and regulatory compliance.

| Aspect | EMS Contract Manufacturing Model | Standard Contract Manufacturing Model |

|---|---|---|

| Flexibility | Access to a broad network of vetted vendors enabling scalable production and alternative sourcing to avoid delays. | Limited to a single facility with no fallback options for delays. |

| Cost | Centralized management of sourcing, assembly, and logistics; competitive global pricing. | Potentially higher costs due to limited sourcing and scaling challenges. |

| Quality Control | Rigorous testing and validation at every stage; adherence to industry standards. | Variable quality without broad oversight or certified processes. |

| Additional Services | Design support, supply chain management, regulatory compliance assistance, and lifecycle support. | Typically limited to manufacturing only, with fewer value-added services. |

| Scalability | Ability to shift production across multiple vendors to meet demand quickly. | Scaling requires long lead times and costly setup adjustments. |

EMS providers deliver design and engineering support, improving product quality and reducing costs.

They manage supplier relationships for competitive sourcing and conduct rigorous testing to ensure standards.

Additional services include logistics, system integration, and regulatory compliance.

EMS companies help OEMs scale production efficiently, maintain high quality, and adapt quickly to market changes. This comprehensive approach sets EMS apart from traditional contract manufacturing models.

Companies that use Electronic Manufacturing Services gain significant efficiency and cost advantages. EMS providers streamline production by leveraging established supplier relationships and advanced management tools. They source high-quality components at competitive prices, which reduces lead times and cost overruns. Many EMS companies operate with vertically integrated models, compressing the supply chain and eliminating extra profit layers. This approach lowers overall costs and improves asset utilization.

Medical device manufacturers and aerospace firms report average cost savings of 10 to 15 percent when outsourcing to EMS partners. These savings come from reduced capital expenditures and the ability to convert fixed costs into variable costs. EMS providers also offer administrative efficiencies in order processing, raw material acquisition, and production planning. A survey of 72 OEMs identified cost, quality, and dependable delivery as the top value factors when choosing EMS partners.

OEMs benefit from:

Improved asset utilization

Quality improvement and agility

Timely delivery and flexibility

Turnkey solutions that streamline production

Quality assurance stands at the core of every successful EMS partnership. Providers like Marsky demonstrate a strong commitment to quality, reliability, and customer satisfaction. Marsky Solutions delivers fast, detailed inspection reports and maintains high standards through rigorous audits and real-time monitoring. Their expertise ensures that products meet strict regulatory and industry requirements.

EMS companies use advanced testing methods, such as automated optical inspection and statistical process control, to maintain consistent quality. They document every step of the manufacturing process, which reduces risks and ensures traceability. Long-term relationships and a global footprint allow EMS providers to deliver reliable results across diverse markets.

Choosing an EMS partner with a proven track record in quality assurance helps companies avoid costly defects and maintain their reputation.

Electronic Manufacturing Services support a wide range of industries. North America leads the global EMS market, driven by early adoption of smart energy management systems and advanced infrastructure. Industrial, commercial, and residential sectors all benefit from EMS solutions. The industrial segment holds the highest market share, fueled by demand for smart technologies and automation.

EMS providers play a vital role in manufacturing, oil and gas, mining, and petrochemical industries. They also serve specialized sectors such as consumer electronics, medical instrumentation, aerospace, defense, IT, telecom, automotive, and robotics. The electronics manufacturing segment accounts for about 38% of the EMS market, reflecting the complexity of next-generation devices and the need for integrated services.

| Sector | EMS Usage Highlights |

|---|---|

| Industrial | Automation, robotics, advanced control systems |

| Consumer Electronics | Mobile devices, smart home products |

| Medical | Instrumentation, diagnostic equipment |

| Automotive | Electric vehicles, infotainment systems |

| Aerospace & Defense | Avionics, mission-critical electronics |

Selecting the right partner for Electronic Manufacturing Services shapes the success of any electronics project. Industry experts recommend a thorough evaluation process. Companies should look for providers with strong technology and manufacturing expertise in their specific industry. The provider’s size and ability to scale with the client’s growth matter. In-house manufacturing capabilities and a strategic location help reduce costs and improve supply chain reliability.

Key criteria include:

Experience in relevant market segments, such as medical, automotive, or industrial electronics

Proven track record with similar product types and volumes

Quality of communication, transparency, and customer focus

Stability and reputation of the management team

Ability to scale production as demand changes

Alignment with organizational goals and product roadmaps

Marsky stands out for its deep market knowledge, robust quality management, and fast communication. Companies should also consider global footprint, sector experience, and adoption of advanced technologies when evaluating EMS partners.

A comprehensive assessment, including reference checks and cross-functional team reviews, ensures a stable and collaborative partnership.

Protecting intellectual property remains a top priority in EMS partnerships. Companies should conduct site visits to verify the provider’s internal IP protection processes. During these visits, they must check for exposed confidential documents and ensure no proprietary information is visible in open areas.

Best practices include:

Documenting all patents and specifying their applicable countries in agreements

Developing an IP playbook strategy for ongoing management

Defining ownership and rights of shared IP, especially in joint development projects

The EMS industry continues to evolve with digital transformation and sustainability at the forefront. Providers now implement IoT solutions, automation, and AI to streamline production and improve quality control. Many invest in green manufacturing, using recyclable materials and energy-saving processes.

| Trend | Description |

|---|---|

| Digital Transformation | Adoption of IoT, AI, and automation for efficient production |

| Sustainability | Use of eco-friendly materials and energy-saving processes |

| Supply Chain Resilience | Real-time monitoring and blockchain for traceability |

| Customization | 3D printing and flexible electronics for personalized products |

| Advanced Workforce Training | Investment in skills for robotics and smart manufacturing |

Providers like Marsky leverage these trends to deliver reliable, innovative, and sustainable solutions.

Selecting the right EMS partner shapes long-term business success. Industry leaders like Marsky demonstrate that strong partnerships drive efficiency, cost savings, and product quality. Companies benefit from proactive risk management, robust supply chain support, and expert guidance. Strategic alliances require careful evaluation, clear communication, and ongoing collaboration. By following proven selection criteria, organizations can build resilient partnerships that support innovation and growth.

An EMS provider designs, manufactures, tests, and distributes electronic products for other companies. They manage supply chains, ensure quality, and offer post-production support. EMS companies help clients bring products to market quickly and efficiently.

Marsky performs thorough inspections, supplier audits, and real-time monitoring. Their team delivers fast, detailed reports and uses advanced technology to detect defects. Clients rely on Marsky for consistent product quality and compliance with industry standards.

Consumer electronics

Automotive

Medical devices

Aerospace

Industrial automation

EMS providers serve many sectors, helping companies innovate and scale production.

| Criteria | Importance |

|---|---|

| Experience | Ensures reliable results |

| Technology | Supports innovation |

| Communication | Improves collaboration |

| Quality Management | Maintains standards |

Companies should evaluate these factors to select the best EMS partner.