Views: 0 Author: Site Editor Publish Time: 2025-08-11 Origin: Site

The biggest difference between apqp and ppap is what they do in quality management.Apqp is a full plan that helps teams at every step of making a product. It helps find problems early and makes things better. Ppap is proof that apqp steps are done and that products meet what customers want. Both help suppliers check their work by making sure people talk often, plan well, and write things down clearly. Companies use these ways to make sure every product is good and that suppliers give parts that follow tough rules.

APQP is a complete plan. It helps teams follow every step to make a product. It helps find problems early. It also helps make the product better.

PPAP is the last check. It shows that parts meet what customers want. It makes sure suppliers can give good products.

APQP and PPAP work together. APQP helps plan and test the product and process. PPAP gives approval before making many products.

Use APQP for new products, handling risks, and making new processes. Use PPAP to approve new parts or changes before making a lot.

Doing APQP and PPAP the right way helps companies make fewer mistakes. It saves money. It also helps buyers and suppliers trust each other.

Advanced product quality planning is a way to help companies make products. It gives steps for teams to follow from start to finish. Teams use APQP to plan, design, and check products. This helps make sure products are good and meet rules. People from different departments work together in APQP. They include engineering and quality control. The main goal is to make customers happy and lower risks. APQP also helps teams work faster and better.

Manufacturers use APQP for many reasons:

Make customers happy by meeting their needs.

Save money and stop mistakes before they happen.

Help workers do their jobs better and faster.

Get new ideas by working together.

Find problems early and fix them.

APQP helps companies make work easier and talk more. Teams can use APQP to make sure products are high quality and follow rules.

The 5 phases of APQP show teams what to do next. Each phase has its own goals and tasks. These steps help teams find problems and do well.

Phase Number | Phase Name | Key Activities and Objectives |

|---|---|---|

1 | Product Planning and Quality Program Definition | Learn what customers want, pick product features, set goals, list materials, and get support from leaders |

2 | Product Design and Development | Finish product design, check for design problems, make samples, set details, and plan tools |

3 | Process Design and Development | Make the process for building, draw process charts, check for process problems, make control plans, and teach workers |

4 | Validation of Product and Process | Test the process and product, run production tests, and check that everything works |

5 | Production Launch, Assessment, and Continuous Improvement | Start making products, watch for changes, get feedback, and fix any issues |

When teams check product design, they make sure it meets all needs. When they check process design, they see if the process makes good products every time. Each phase helps build strong quality and keeps making things better.

Tip: Companies like Marsky Solutions use APQP to help clients check suppliers and inspect quality. This makes sure every step follows world standards.

PPAP means Production Part Approval Process. This method helps show that parts meet what customers want before making many of them. In car and factory work, ppap is a set way to check quality. It makes sure suppliers can always give parts that follow tough rules. PPAP is part of APQP and matches world rules like ISO 9001 and IATF 16949.

PPAP has many steps like writing down info, checking, and getting approval. These steps help stop problems and make quality better. The process also helps suppliers and makers talk more clearly. By using ppap, companies can stop mistakes and confusion. The main goals are to lower risks, make quality better, and keep customers happy with good parts.

Note: Marsky Solutions uses ppap to help clients make sure suppliers can meet all quality and rule needs before making lots of products.

PPAP rules focus on checking products and how they are made. Suppliers must give proof and papers that show their work can make parts that fit all needs. The ppap package has many parts, each one checks quality at a different step.

PPAP Submission Levels | Description |

|---|---|

Level 1 | Only the Part Submission Warrant (PSW) goes to the customer |

Level 2 | PSW with some product samples and a little extra info |

Level 3 | PSW with product samples and all needed info |

Level 4 | PSW and other things the customer asks for |

Level 5 | PSW with product samples and all info ready at the supplier’s factory |

Important parts of a ppap package are:

Design records and papers about changes

Customer approval from engineers

Size checks and material test results

Control plans and process maps

Failure Mode and Effects Analysis (DFMEA & PFMEA)

Checks on how things are measured

First process studies and lab papers

Looks approval report and sample parts

Part Submission Warrant (PSW)

These rules can change in different jobs. For example, cars use the AIAG PPAP Manual. Planes use SAE AS9145. Electronics change ppap steps to fit their own quality checks.

APQP and PPAP help companies check supplier quality. APQP gives teams steps to plan, design, and build products. PPAP is the last check to make sure parts meet what customers want. Many car and plane companies use both to follow rules like ISO 9001, IATF 16949, and AS9145.

APQP leads teams through steps like risk checks, process planning, and testing. PPAP is part of the testing step. Suppliers send papers and samples to show they are ready to make parts. Using both helps teams find problems early, talk better, and make products better.

Stories from real companies show APQP and PPAP together cut mistakes, save money, and make customers happy. Teams use APQP to plan each step. PPAP checks and approves the final process before making lots of products.

APQP Phase | Description | Role of PPAP |

|---|---|---|

Planning | Set goals and needs | N/A |

Product Design & Development | Make product plans and details | N/A |

Process Design & Development | Plan how to build products | N/A |

Product & Process Validation | Test if making parts works well | PPAP checks and approves |

Ongoing Production & Service | Watch and help products after launch | N/A |

APQP and PPAP are important for checking quality in jobs with strict rules. APQP helps teams plan, design, and watch products using clear steps. It uses tools like DFMEA and PFMEA to find and fix problems early. PPAP gives proof that making parts always meets the design.

APQP helps teams work together and plan projects to meet customer and rule needs.

When designing products, teams use APQP to work with suppliers, pick key features, and write instructions.

PPAP is the main check in the testing step. It gives proof like design papers, process charts, and check reports.

APQP and PPAP together lower risks, help approve suppliers, and make sure rules are followed.

Marsky Solutions uses APQP and PPAP to help clients check suppliers, look at quality, and see if making parts is ready. This way, products are safer and work better. It also helps buyers and suppliers trust each other.

APQP and PPAP have different jobs in quality management. APQP is like a map for making products. It helps teams from the first idea to the final product. APQP helps companies plan, design, and make products better. Teams use APQP to find risks and work together. They also make sure every step follows the rules.

PPAP checks if a supplier can always make good parts. Companies use PPAP when they make new parts or change old ones. PPAP gives proof that the process is ready for big production. If PPAP does not pass, it shows there may be problems with APQP. This means APQP and PPAP work closely together.

Marsky Solutions uses APQP to help clients plan and watch suppliers from the start. The company uses PPAP to check if suppliers can give good parts before making many.

Key differences in purpose:

APQP looks at the whole product life, focusing on planning, design, and getting better.

PPAP checks if making parts is ready, making sure parts follow rules.

APQP uses teams from different jobs and finds risks early.

PPAP gives proof and papers for approval before making parts.

PPAP is a big checkpoint in APQP’s testing step.

APQP covers a lot. It looks at every step from planning to making and improving products. Teams use APQP to handle design, process, testing, and feedback. Many groups help, like engineering, quality, and supply chain.

PPAP has a smaller job. It checks and approves making parts. Suppliers must give papers like design records, control plans, FMEAs, and measurement checks. PPAP makes sure the process can always make good parts.

APQP helps pick suppliers and check their work by looking at skills, risks, and how they do. PPAP checks if suppliers can give approved parts after changes in tools, materials, or ways of working.

Aspect | APQP | PPAP |

|---|---|---|

Coverage | Full product lifecycle | Production part validation |

Activities | Planning, design, process, validation | Documentation, approval, compliance |

Documentation | Broad, cross-functional | Detailed, focused on 18 key elements |

Supplier Integration | Early and ongoing | At validation and approval stage |

Continuous Improvement | Yes | No (focuses on readiness and compliance) |

Marsky Solutions helps clients with APQP and PPAP. The team checks suppliers, looks at papers, and does audits to make sure rules are followed.

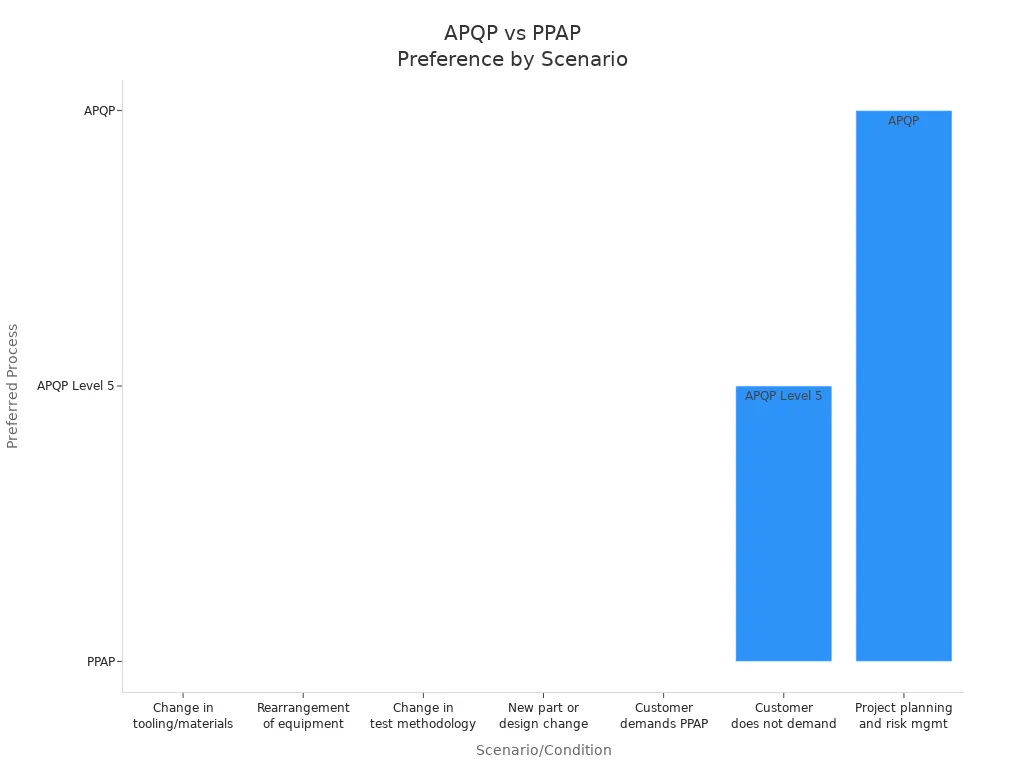

Companies pick APQP or PPAP based on what they need and where they are in making products. APQP is best for planning, finding risks, and building processes. Teams use APQP for new products, fixing old ones, or handling big supply chains.

PPAP is needed for new parts, design changes, or changes in how things are made. It is also used after changes in tools, materials, or checking methods. PPAP gives the last approval before making lots of parts.

Scenario/Condition | Preferred Process | Explanation |

|---|---|---|

Change in tooling, materials, or manufacturing process affecting product quality | PPAP | Checks and approves parts after changes. |

Rearrangement or refurbishment of equipment/tooling | PPAP | Makes sure new tools make good parts. |

Change in test or inspection methodology | PPAP | Checks if new ways still keep quality. |

New production part or engineering change in design/specification/material | PPAP | Approves new or changed parts. |

Customer demands PPAP (unspecified level) | PPAP | Use Level 3 PPAP submission. |

Customer does not demand PPAP | APQP Level 5 | APQP covers making and after delivery. |

Overall project planning, risk management, process development | APQP | APQP handles quality for the whole product life. |

Real-world examples:

Company Type | Chosen Approach | Project Requirement / Outcome |

|---|---|---|

Global Automotive Tier-1 Supplier | PPAP | Approval times dropped by 40% and fewer redesigns. |

Electronics Manufacturer | APQP | First-pass yield went up by 25% with APQP training. |

Medical Device Manufacturer | APQP | Passed all inspections and got faster market approval. |

Wind Turbine OEM | APQP (APQP4Wind) | Blade quality got better, with fewer failures and lower costs. |

Marsky Solutions helps clients pick APQP or PPAP. The team guides buyers through audits, checks, and process tests. Clients get expert help to make sure every product meets tough rules.

Tip: For audits and quality checks, use APQP for big planning and risk checks. Use PPAP for special part or process changes that need approval.

Some people think APQP and PPAP are the same. Others believe their steps mix together. This mix-up can cause mistakes in checking quality and supplier audits. But APQP and PPAP do different jobs in making products.

APQP helps with new product design and launch. Design and product engineers use APQP to plan and improve products before making them.

PPAP is about approving the way parts are made. Manufacturing and quality engineers use PPAP to check if the process makes parts that meet what customers want.

Some people think PPAP is just paperwork or not as important as APQP. That is wrong. PPAP is very important for stopping problems in making things and keeping quality high.

Recalls and warranty claims can happen because of design mistakes (APQP), making mistakes (PPAP), or supplier problems. Many recalls come from making mistakes, which PPAP helps fix, especially in medical devices.

Experts say APQP is the main plan for quality. PPAP is the approval step inside APQP. APQP helps teams with design and process planning. PPAP checks if parts made in production meet all needs. Both help teams check quality and manage suppliers.

Using APQP or PPAP the wrong way can be risky for companies and buyers. If teams do not use these steps right, they might miss big risks or not stop problems.

Skipping risk checks like FMEA can let failures go unnoticed in making products.

Bad process controls and not stopping problems early can lead to more defects. This hurts product quality and following rules.

Only checking finished products is not enough. Without good risk checks in APQP and PPAP, teams may not stop problems before customers get products.

Not working together to find and fix risks can leave big problems. This can hurt safety, how things work, and following rules.

Marsky Solutions helps clients avoid these problems. The team guides clients through every APQP and PPAP step. They make sure risk checks, process checks, and supplier audits are done right. This helps control quality, lowers recalls, and builds trust between buyers and suppliers.

Tip: Companies should use APQP and PPAP to check quality and suppliers before problems happen. Do not treat them as just lists or paperwork. Using them well makes products safer and supply chains work better.

APQP helps teams plan, manage risks, and keep making things better. PPAP is the last check to see if suppliers can meet quality rules every time. Both help lower mistakes and make approvals faster. Companies should use APQP when starting new projects or changing how things are made. After that, they use PPAP to make sure production is ready.

Marsky Solutions helps clients use APQP and PPAP. This makes sure suppliers are checked and every shipment has good quality.

APQP helps teams plan and make products. PPAP checks if making parts always meets what customers want. APQP looks at every step from start to finish. PPAP is used for the last check before making lots of parts.

Companies use APQP for new products or fixing old ones. It is also good for big supply chains. APQP helps find risks early. It helps teams talk better and keep quality high from the first idea to delivery.

PPAP gives proof that suppliers can make good parts. Auditors use PPAP to see if suppliers are ready to make many parts. This lowers the chance of mistakes in products sent to customers.

Marsky Solutions checks suppliers and looks at quality. The team makes sure suppliers follow APQP steps. They also check if PPAP rules are met. This helps clients get good products every time.

Yes. APQP and PPAP help buyers in other countries check quality. They lower risks and make sure suppliers follow tough rules. Marsky Solutions uses these ways to help clients pick good suppliers and get safe products.